Introducing the Unsung Heroes of the Industrial World: Industrial Valves

In the vast and complex world of industrial infrastructure, there are countless components working tirelessly behind the scenes to ensure the smooth operation of various processes. Among these unsung heroes, industrial valves stand out as crucial elements that often go unseen and underappreciated. These unassuming devices are the gatekeepers of fluid control, regulating the flow of liquids and gases, and playing a pivotal role in maintaining the efficiency and safety of numerous industries.

One type of industrial valve that deserves attention is the wedge gate valve. Known for its reliable sealing capabilities, this valve utilizes a wedge-shaped gate that moves up and down to control the flow of fluids. The wedge gate valve is commonly used in pipelines, oil and gas refineries, and chemical plants, where it proves its worth by effectively controlling the pressure and direction of liquids, thus preventing leaks and ensuring the integrity of the system.

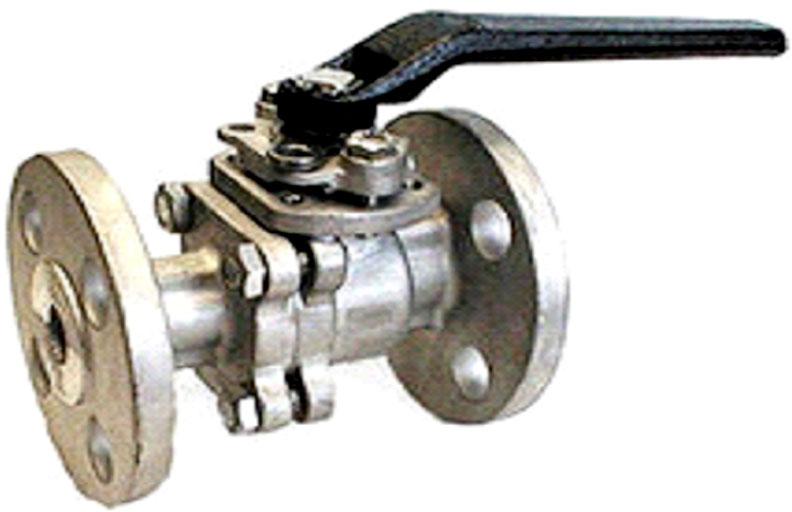

Another vital component in the world of industrial valves is the flanged gate valve. This robust valve is favored for its durability and versatility. Its flanged design allows for easy installation and removal, making it convenient for maintenance purposes. Additionally, the flanged gate valve excels in applications with high-pressure environments, such as power plants and water treatment facilities, where it effectively manages the flow of fluids while maintaining the system’s stability and reliability.

When it comes to controlling water flow, the water gate valve takes center stage. Widely used in municipal water distribution systems, these valves provide an efficient means of regulating water supply to households, commercial establishments, and industrial facilities. Their design allows for precise control over water flow, ensuring an optimal distribution while minimizing wastage. Without the trusty water gate valves, our daily lives would undoubtedly be impacted, highlighting their importance in maintaining the smooth functioning of our modern infrastructure.

Last but certainly not least, the cast iron gate valve is a prominent figure in industries where durability and resistance to corrosion are paramount. These valves are specifically designed for heavy-duty applications that require a strong and long-lasting solution. With their ability to withstand harsh environments and extreme temperatures, cast iron gate valves are integral to sectors such as power generation, mining, and chemical processing, where reliability and longevity are essential for uninterrupted operations.

As we delve deeper into the world of industrial valves, it becomes evident that these unassuming devices possess immense power and significance. From the practicality of the wedge gate valve to the adaptability of the flanged gate valve, from the necessity of water gate valves to the resilience of cast iron gate valves, these unsung heroes are the backbone of various industries, ensuring the smooth and efficient flow of fluids that drive our modern society forward.

Importance of Industrial Valves

Industrial valves play a crucial role in numerous industries, serving as vital components that help control the flow and direction of fluids such as water, oil, gas, and chemicals. These unsung heroes of the industrial world ensure the smooth and efficient operation of various processes, ensuring safety, reliability, and productivity.

One prominent type of industrial valve is the wedge gate valve. Designed with a sliding gate between two inclined seats, this valve effectively controls flow by either fully opening or completely closing the passageway. Its robust construction and ability to withstand high pressure and temperature make it a popular choice in industries such as oil and gas, chemical processing, and power generation.

Another commonly used type is the flanged gate valve. This valve, featuring flanged ends for easy installation and maintenance, provides a tight shut-off with its straightforward yet effective design. Its versatility and ability to handle various fluids and pressures make it an indispensable component in sectors including water treatment, manufacturing, and wastewater management.

The water gate valve, specifically designed for water control applications, ensures reliable operation of water distribution systems, irrigation networks, and wastewater treatment plants. Its corrosion-resistant materials and user-friendly design allow for efficient flow regulation, preventing water wastage and ensuring the smooth functioning of these essential infrastructures.

Lastly, the cast iron gate valve offers durability and longevity with its strong cast iron body. This valve is widely utilized in plumbing systems, heating, ventilation, and air conditioning (HVAC) systems, and fire protection systems. Its ability to withstand high pressures and temperatures, along with its exceptional resistance to corrosion, make it an indispensable component in these critical areas.

In conclusion, industrial valves, including the wedge gate valve, flanged gate valve, water gate valve, and cast iron gate valve, are of utmost importance in various industries. Their ability to regulate fluid flow ensures the safety, efficiency, and reliability of industrial processes, making them an essential component of modern-day infrastructure.

2. Understanding the Different Types of Gate Valves

Gate valves are essential components in various industrial applications, offering efficient control over the flow of fluids. In this section, we will explore three commonly used types of gate valves: the wedge gate valve, flanged gate valve, and water gate valve. These valves play a crucial role in ensuring the smooth operation of industrial processes.

The wedge gate valve is a versatile valve design widely used in different industries. It consists of a gate with a wedge-shaped disc that moves up and down to control the flow of fluids. The wedge gate valve offers excellent sealing capabilities, making it ideal for applications where a tight shut-off is required. Its simple yet effective design allows for easy operation and reliable performance.

Another type of gate valve is the flanged gate valve. As the name suggests, this valve is equipped with flanged ends that allow for easy installation and connection with the pipeline system. Flanged gate valves are commonly used in industries such as oil and gas, water treatment, and chemical processing. They offer high-pressure capabilities and are known for their durability and long service life.

The water gate valve, as its name implies, is specifically designed for water applications. It features a resilient seat that provides a watertight seal when the valve is closed. Water gate valves are commonly used in municipal water supply systems, irrigation systems, and firefighting applications. These valves ensure reliable control over the water flow, allowing for efficient water distribution and management.

Gate Valve Manufacturer

In conclusion, understanding the different types of gate valves is crucial for selecting the appropriate valve for specific industrial applications. The wedge gate valve, flanged gate valve, and water gate valve each have their unique characteristics and advantages, catering to different requirements and operating conditions. By choosing the right type of gate valve, industries can ensure efficient fluid control, enhancing the overall performance and productivity of their processes.

3. Exploring the Applications of Cast Iron Gate Valves

Cast iron gate valves are essential components in various industrial settings due to their reliable performance and durability. These valves find wide-ranging applications in different sectors, thanks to their robust construction and ability to withstand high pressures. In this section, we will delve into some key areas where cast iron gate valves play a crucial role.

The first notable application is in water treatment plants. Cast iron gate valves are frequently used to control the flow of water in treatment systems, allowing for efficient filtration and purification processes. These valves provide a tight seal, ensuring that water does not leak or get contaminated during the treatment stages. Moreover, their easy operation and low maintenance requirements make them highly suitable for large-scale water treatment facilities.

Another important application of cast iron gate valves is in the chemical industry. These valves are utilized in pipelines to regulate the flow of various chemicals, including acids, solvents, and corrosive substances. The sturdy construction of cast iron gate valves enables them to withstand the corrosive nature of such chemicals, ensuring safe and efficient transportation within industrial settings. Additionally, their ability to handle high pressures makes them indispensable in chemical processing plants.

Furthermore, cast iron gate valves are widely employed in irrigation systems for agricultural purposes. These valves effectively control the flow of water in irrigation pipelines, helping to optimize water distribution and conserve this valuable resource. The durable nature of cast iron gate valves ensures their longevity in outdoor and challenging environments, making them an ideal choice for agricultural applications.

In conclusion, cast iron gate valves are versatile components with a range of applications across different industries. Their usage in water treatment plants, chemical processing facilities, and irrigation systems highlights their reliability and resilience. With their ability to handle high pressures and corrosive substances, cast iron gate valves continue to be invaluable tools in ensuring the smooth and efficient functioning of various industrial processes.