CNC Machining & Manufacturing

Machining offers some amazing features to it when choosing a manufacturing method. This method involves the removal of material. This means that the “start” of your products would consist of a block of metal. A couple common materials for fractional laser treatments are stainless steel, and wood. Particularly with CNC cutting, a range of pieces can be built from these “blocks” of material. Essentially, a drill will fallen and it will carve, remove material, and cut pieces of material offline. Other parts within machining exist also to remove material. This is great to create small quantities of brand. It doesn’t offer the variety, may also be design capabilities of 3d printing, however, it can surpass mold manufacturing in several situations.

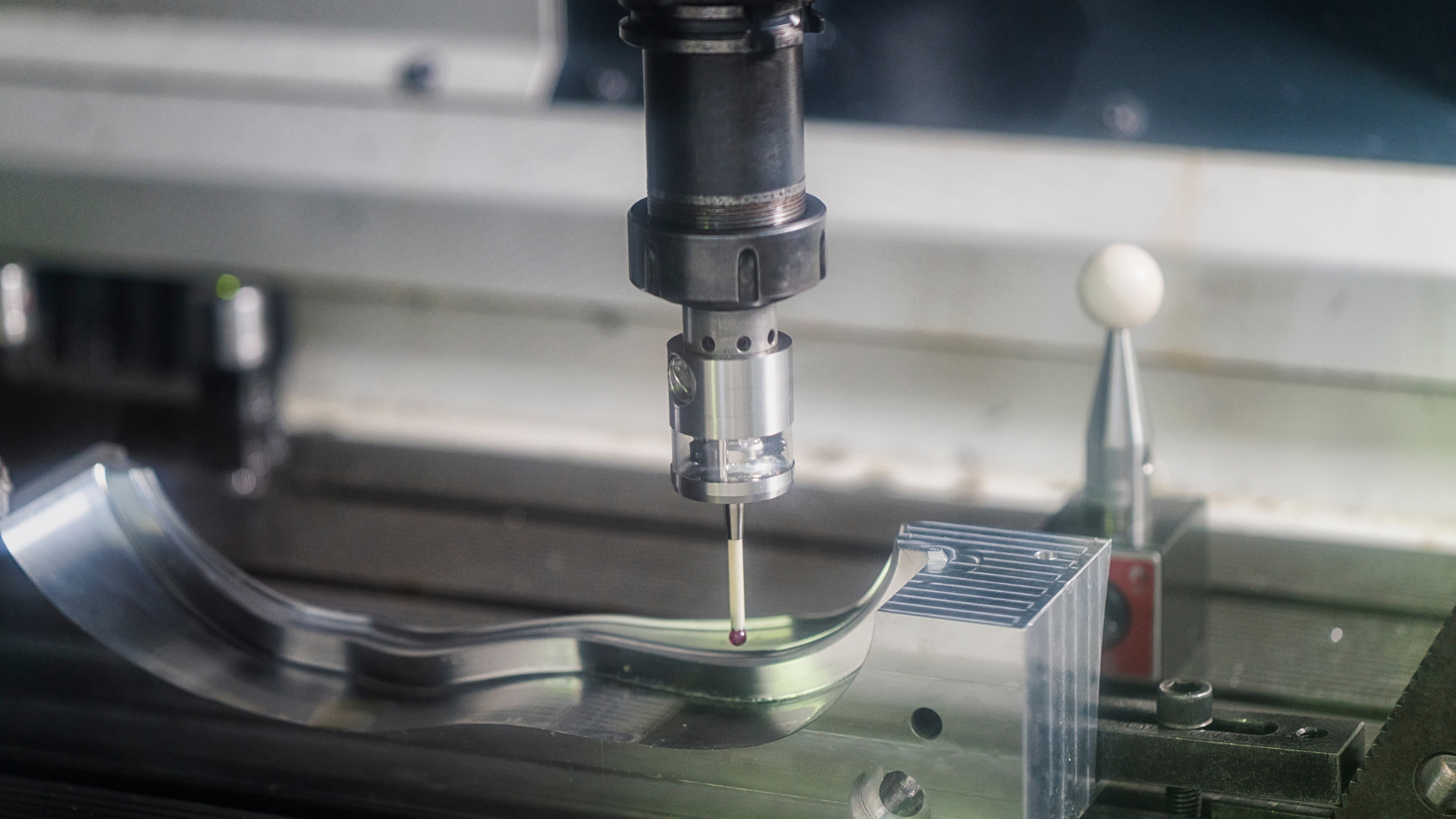

CNC is the better machine thatrrrs available that looks after Turning, Drilling, Grinding and Milling, causing all of this together. Computer Numeric Control or CNC is really here to keep.

Contingency in Quoting – Always put a small 3-5% contingency to quotes. Tasty cover the inevitable price increases or expedited shipping or other unforeseen charge that will break your profit profit.

Cutting tools – never order the made in china cutting tools. A $25.00 Created in USA end mill will out perform the $10.00 Import any day’s the some days. Expect to go through 3 import Endmills to 1 domestic end mill. Can teach you add into a cutting tool overhead, lower that per piece volume and add to tool change cycle situations. Also don’t be afraid to purchase around for this cutting options. Many tool vendors are having the same problem you are situated in and will sell you tools for just a very low mark high. If at all possible speak with someone plus a vendors inside sales department. Many tools can be offered with great quantity discounts a person pool your order and just ask for a discount.

After the carefully considered your setup and selected the proper tooling, will be important to put it in its entirety. Start by using the mid array of the speeds/feeds provided by the tooling build. Then adjust your speed/feed to find optimum cutting conditions for your job. Keep close and careful record of your adjustments. Record how long the tooling lasts each and every speed/feed venue. This information is vital to good tool life organizational. By optimizing the cutting process, totally . see longer tool life and lower overall tooling costs.

Overflow Work – Find the largest shops in town and offer overflow occupation. Many large machine shops love addressing small shops, the reason is that’s instantly expand their workforce and machining capability for any lower rate then there own. This assists CNC Machining them their particular tight deadline critical contracts.

The control computer gets control software loaded about it. You start up the control software then load inside CNC Program you started. When you do this, the G-Code will be visible and able to go. Possess prep your CNC Machine and zero it out, you may turn your “cycle.” A cycle is usually completing one CNC Program, which is a machining set. You will also hear the term “Cycle Time” on the professional side of CNC a lot more. The quicker you can obtain the cycle time, the more parts you may make. And yes, that translates to more hard earned money.