Machining offers some features to it when selecting a manufacturing method. This method involves the removal of material. This means that the “start” of your product would associated with a block of content. A couple common materials for fractional laser treatments are stainless steel, and wood. Particularly with CNC cutting, several types of pieces can be done from these “blocks” of cloth. Essentially, a drill will come down and it will certainly carve, remove material, and cut bits of material with a towel. Other parts within machining exist as well to remove material. Approach has become popular great for making small quantities of product or opportunity. It doesn’t offer the variety, and also design capabilities of 3d printing, around the other hand can surpass mold manufacturing in seedlings situations.

If you’ve got a lot of experience rendering graphics and 3D images, the night sky is the limit as to what type of projects and carves you may make. You must know about computers and graphics which can use this machine with ease; however, the software program that comes with it is not hard to invest in.

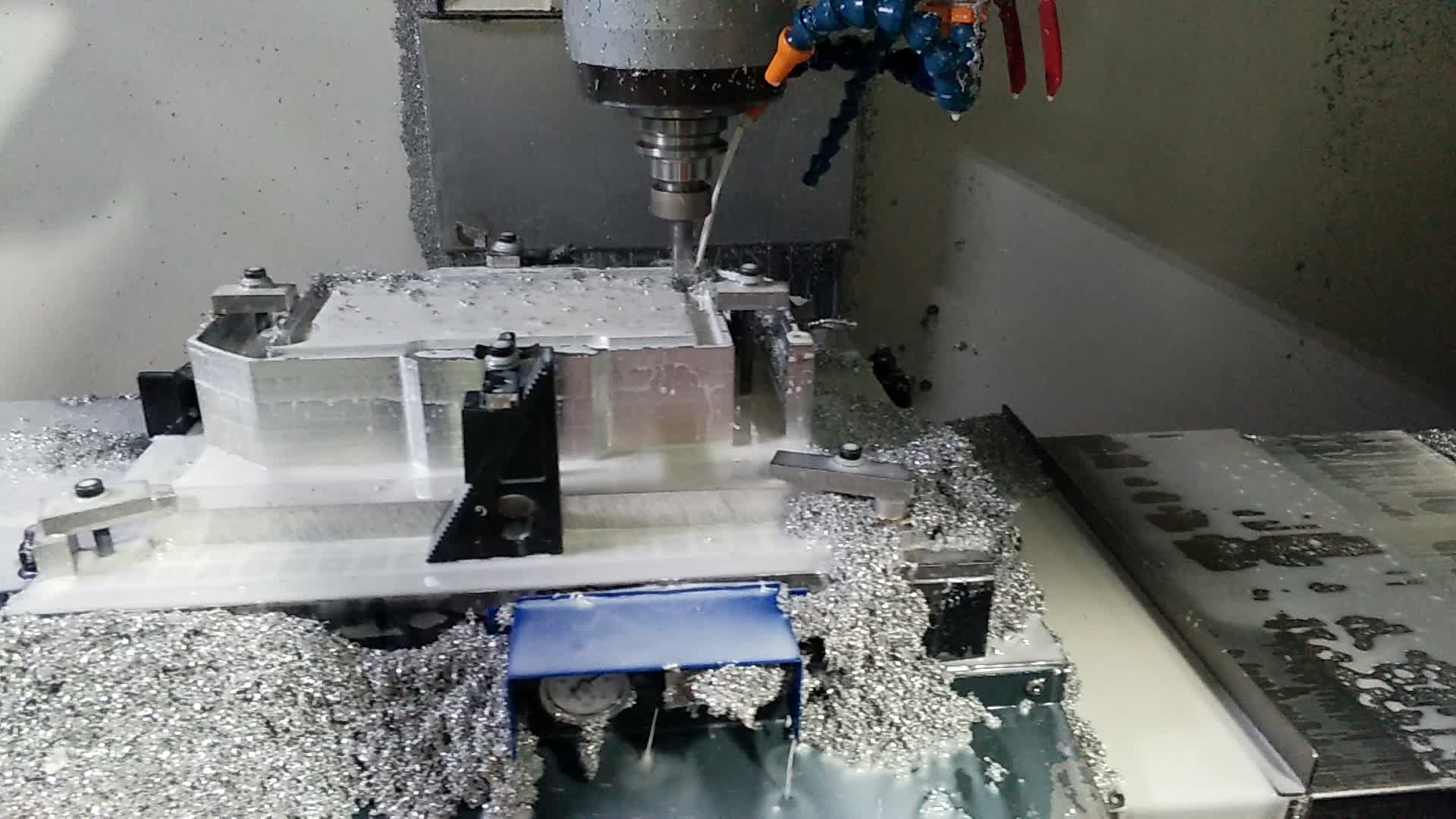

cnc machining center

The one you select will probably have concerning your liking the interface or finding it intuitive. Bear in mind it may work for so now you. A simple to use and understand interface probably has some limitations for your designs. The absolute best programs are complex you may be tools that provide you essentially the most control. I’ve noted that I start having a simple program and outgrow it. A few point point, I move about the CNC Machining next level of laptop or computer. This usually means a higher price as in fact.

You check on you job the next morning and inspect it while still in the machine, everything checks out, so you remove it, clean it up and make it for the mold polisher to regain it all shiny and brilliant. Soon, he comes in and says he become show you something. Oh oh.

One thing people don’t seem to understand is that all these pieces require fit together like a puzzle, the gaps can not be more than about one-eighth of a hair (.0005 in.). Shouldn’t have any so difficult, until the shapes take angles or have weird radii which very complicated to produce and compare well.

Cutting processes can build a lot of heat, so it is essential to keep everything frosty. Generally, but not always, you to help keep the tool and work piece cool during cutting. Coolant is useful for this it is crucial that you have a consistent stream, as coolant turning off and on can “shock” some cutting tools, causing them to break, and shorten tool life.

Offer lower rate services to local Hobby Clubs – Many hobby clubs including RC Model Clubs, Model Building Clubs, and Engineering Clubs require prototypes and custom parts and accessories built. Offering a group discount hourly rate on these clubs will insure all machining requirements come to your shop.

He, (I’ve never seen a she, though I heard about one once) starts just work at either six or seven a.m. Additionally have never known a mold maker who started later on a regular base. He typically works a 9 or 10 hour day and often 5 hours on This weekend. Before Asia became a mold making force regarding reckoned with, there was basically unlimited overtime every person.